Loading... Please wait...

Loading... Please wait...Categories

New Products

-

$129.00$109.00 -

$79.20

-

$44.40

-

$15.75

-

$19.00

Our Newsletter

- Home

- Proxxon Tools

- Table top machines

- PROXXON MICRO Mill MF 70 #27110

- Home

- Proxxon Tools

- Pecision Milling Systems

- PROXXON MICRO Mill MF 70 #27110

- Home

- Milling Machines

- PROXXON MICRO Mill MF 70 #27110

- Home

- Table top machines

- PROXXON MICRO Mill MF 70 #27110

Product Description

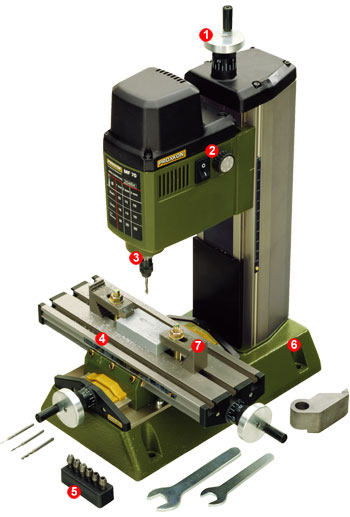

MICRO miller MF 70

Base of grey cast iron. Including both vertical column and compound table of treated, quality aluminium. All axes are play-free and have adjustable gibs. Headstock of die-cast aluminium contains the 24 pole special (balanced) motor is super stable even at high operating speeds. This stability facilitates the use of the finest cutters. The triple slit, hardened steel MICROMOT collets cover 1.0 - 1.5 - 2.0 - 2.35 - 3.0 - 3.2mm. The table is fitted with 3 T-slots of the 12 x 6 x 5mm MICROMOT norm. An adjustable ruler scale eases the positioning of the workpiece. All handwheels are zero adjustable with 1 revolution 1.0mm, 1 division 0.05mm.

Technical data:

220 - 240V, 100W, 50/60Hz. Spindle speeds 5,000 - 20,000rpm. Table 200 x 70mm with X-Y travel of 134 and 46mm respectively, with vertical travel 80mm. Footprint size 130 x 225mm and overall height 370mm. Weight approx. 7kg. The clamping blocks depicted are included too, but not the workpiece!or end mills.

NO 27 110

|

|

Tungsten milling cutters

Two flute cutters and a fishtail profile ensure cutting to the centre, allowing boring. Usable on grey cast iron, hardened cast iron, steel, cast steel, brass, aluminium, glass and even plastics and carbon fibre. One each of 1.0 - 2.0 and 3.0mm. 3.0mm shaft diameter.

NO 27 116 3 pieces

Tungsten milling cutters, separately

See description above.

|

|

A 1,0 mm |

|

|

|

B 2,0 mm |

|

|

|

C 3,0 mm |

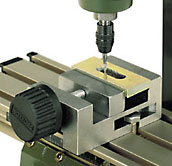

Milled from steel for precision. Completely angular. Jaw width 46mm, clamping capacity 34mm. Total length 70mm. Especially suited for filigree and accurate working with the MICRO miller MF 70 or the MICRO compound table KT 70. Sliding blocks and fixing screws included. Comes in a wooden box.

NO 24 260

Die-cast zinc. With three machined sides. The slot fits the adjustable fence of the drill stand MB 140/S and bench drill TBM 220. Horizontal and vertical V-slots in jaw. Jaw width 50mm and height 10mm. Maximum clamping width 34mm.

NO 28 132

Dividing head for MICRO miller MF 70 and MICRO compound table KT 70

For machining circular work pieces, manufacturing off-set holes and milled out portions, milling key surfaces, four-sided, sixsided materials, etc. Absolute accurate division due to nonius at the base body. With reversed chuck jaws: Capacity inside 1.5 to 32mm, outside 12 to 65mm. Bore of 11mm (for processing longer spindles in a vertical position). With fastening bores for horizontal and vertical mounting and suitable slot nuts and fastening screws for mounting to the MICRO miller MF 70 and the MICRO compound table KT 70. Size 72 x 64 x 38mm. In wooden box with sliding lid.

NO 24 264

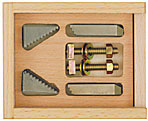

The step clamps set is supplied with the KT 70, but can also be ordered separately. Set consists of 2 stepped blocks and clamps, T-slot nuts of the MICROMOT standard (11.5 x 11 x 4mm), bolts. This set also fits the mill/lathe systems PD 230/E and PD 400.

NO 24 256

NO 28 765

Find Similar Products by Category

Customers Who Viewed This Product Also Viewed

-

$2,242.00

-

$1,531.00

-

$1,335.00

-

$490.00

-

$201.00

-

$415.00

-

$2,802.00

-

$95.00